10/12/16L 110V/60Hz ULV DisinfectantFogger Knapsack Electric Sprayer Fogging Machine Fine Mist Sprayers

10/12/16L 110V/60Hz ULV DisinfectantFogger Knapsack Electric Sprayer Fogging Machine Fine Mist Sprayers

100 in stock

Couldn't load pickup availability

Specifications:

ltem No. |

KB-15003E |

KB-15002E |

KB-15006E |

Tank Capacity |

16L (4Gal) |

12L (3Gal) |

10L (2-% Gal) |

Packing size |

43x20x53cm |

39x20x43cm |

47x19x48cm |

Net Weight |

4.2 Kg |

3.5 Kg |

4.1 Kg |

Gross Weight |

5.0 Kg |

4.3 Kg |

4.9 Kg |

Rated voltage |

110V/60Hz |

||

Motor Power |

1200W |

||

Particle Size |

0-50 μ m (Adjustable) |

||

Max Flow Rate |

750 ML /min |

||

Horizontal Coverage |

5 to 6 Meter |

||

Vertical Coverage |

1.5 to 2 Meter |

||

We will send you the adapter according to your country.

IF you want an sprayer 220V / 50 Hz please search for ID: 1667502

Package included:

1* ULV electric Sprayer

Features:

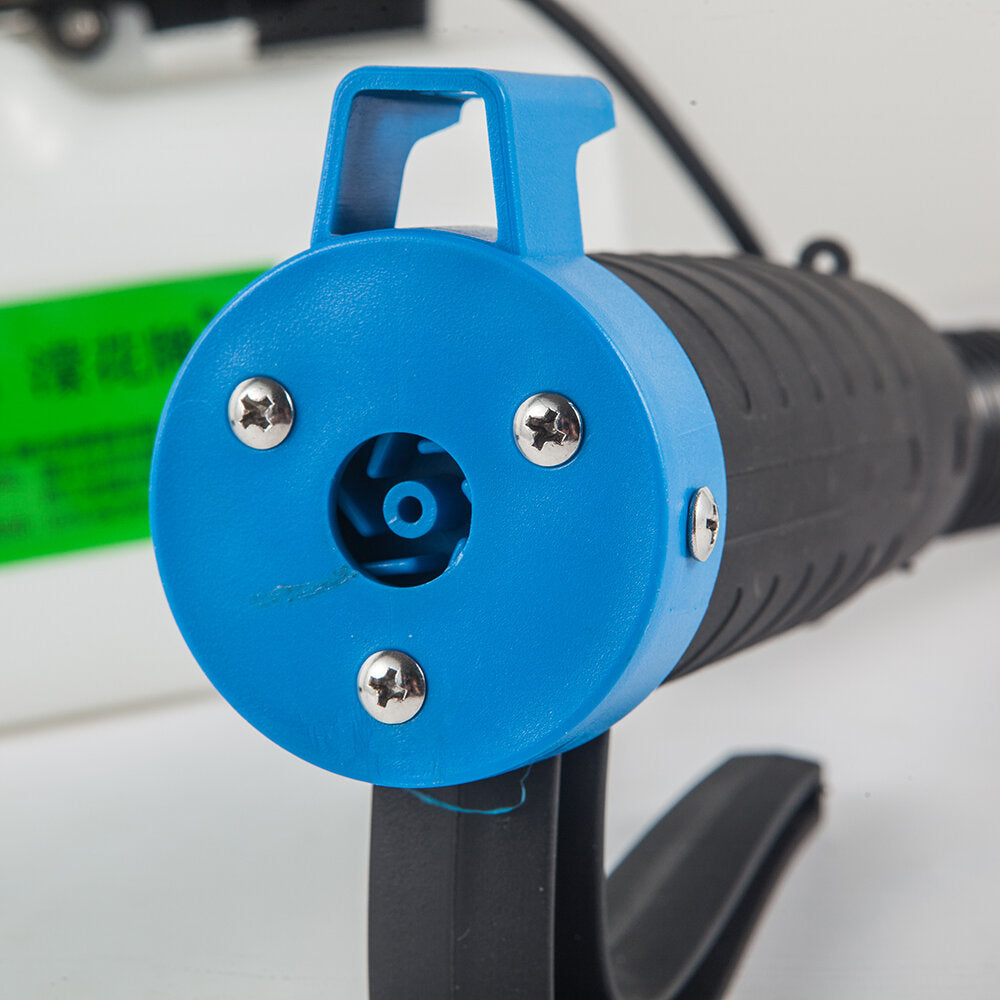

The sprayer has the advantages of high efficiency, uniform droplet. Long spray range, supporting with high-performance motor, stable performance, reliable and durable.

Application:

It is specially applied for large area spraying operation of greenhouse. It can also be used for Public sanitation and disinfection, such as airports, docks, hotels, restaurants, hospitals, public transport, theaters, communities, entertainment. As well as food processing, pharmaceutical companies, animal husbandry industry's disinfection and sterilization, health and epidemic prevention.

Operation

â‘ Preparation: plug into power; tum on the power switch to check the motor if running correctly, add the chemical after filtered with the filter funnel, tighten screw the tank lid.

â‘¡ Power on: tum on the power switch (ON), adjust the spray volume to appropriate requirements, then start to spray.

â‘¢ Power of; Raise the spray nozzle higher than chemical tank, turn OFF power switch, keeping 2-3 seconds. The purpose is to let the remaining liquid in the pipe reflux into the tank, to avoid the chemicals back up into the pipe and cause the motor moisture damage. Lastly turn off the adjusting nut, to prevent the chemical outflow when adding liquid next time.

â‘£During the sprayer working. the high speed gas flow will cause the spray lance and pipe heating, it is a normal phenomenon.